Thermic Fluid Heater - Solid Fuel Fired

We offer a wide range of Thermic Fluid Heater - Solid Fuel Fired such as thermic fluid heater-solid fuel fired thermic fluid heater and many more. These systems are used to heat up the thermic fluid and offers high reliability under extreme pressure conditions and find wide application for indirect process heating applications. Our ranges of products are used in various industries like textile, intermediate, pharmaceutical and dairy. These products are highly demanded for their optimum performance and available at market leading prices.

Thermic Fluid Heater/ Solid Fuel

Model : TSCV

Stationary Grate Combustion Technology is best suited for fuels like Wood Waste, Coal, Lignite, Briquettes, etc with manual feeding into furnace.

Model : TSAW

Stationary grate combustion technology with auto feeding is best suited for fuels like Wood chips, briquettes, Agro waste with manual feeding into furnace & paddy husk, saw dust, etc with auto feeding by screw feeder.

Model : TSFB

Fluidized bed combustion technology is best suited for fuels like low grade coal, paddy husk. Petcock, pellets, etc with auto feeding system of over bed & under bed into Furnace.

Salient Features of This Model

Furnace is designed for multi fuel options, with major thrust on proper selection of combustion grate, furnace height, combustion volume, fuel feeding systems. To ensure efficient combustion & lesser heat loss.

Coils are designed with optimum flow consideration to gain maximum heat from flue gases. Coils are tested at 3 stages before final dispatch as a part of Thermotech's stringent quality control.

ID Fan, FD Fan & booster fan (in any) are selected as per fuel's perfect air-fuel ratio requirement, which ensures optimum air quantity for combustion & thus saves power consumption.

Expansion Tank capacity is specifically selected after consulting total holdup of Thermic Oil. Deaeration Tank is specially designed considering flow & temperature requirement.

Thermotech offers complete solution of Thermic Fluid heating system along with Pipeline, Pollution control equipments, fuel handling, etc on Turnkey basis.

Auto Controls & Safety

1.Thermic Fluid Temperature control

Digital temperature indicator-cum-controller cut of ID/FD fan of preset temperature and restart of preset temperature and restart of preset differential temperature to maintain system temperature.

2.Stack Temperature Control

A blind temperature controller cut of ID/FD fan and sound alarm if stack temperature exceeds to preset temperature.

3.Low/NO Flow of Thermic Fluid

Differential pressure switch connected across intel and outlet headers signals low flow alarm in case of low fluid pressure of Thermic fluid in coils.

4.Low Level of Thermic Fluid

The visual level indicator and float actuated lever switch fitted in expansion tank signals alarm in case of low level thermic fluid in the system.

5.Thermic Fluid Pump Motor Trip

In case of thermic fluid pump motor trip, electrical interlocks, cut off ID/FD fan.

6.Power Failure

Diesel engine drive keeps thermic fluid moving in the system to prevent its degradation and overflow.

7.Excess Furnace Bed Temperature

Digital temperature indicator-cum-controller senses furnace bed temperature and cut off ID/FD fan above set value(for FBC unit).

Benefites :

Multi-Fuel Option

Low Power Consumption

Energy Optimization

Low Maintenance

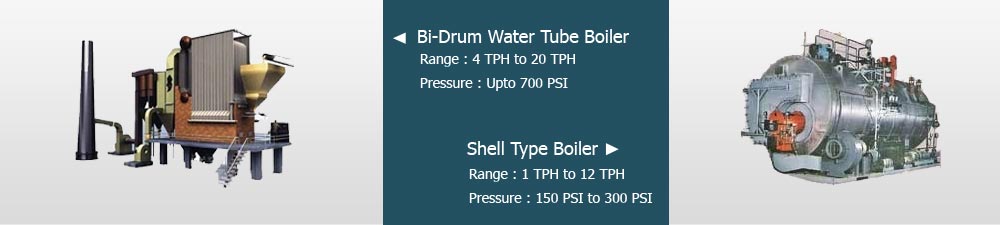

Generators,Boilers & Burners

Testimonials

"Our clients can avail from us high quality range of Packaged Smoke/Fuel Tube Boilers (IFB & AOF) which are widely used in various industrial applications."